There’s something special about owning something made just for you — no shortcuts, no mass production, just quality and care in every stitch. That’s exactly how we approach every headboard at Fabric & Frame.

Here’s how your bespoke piece comes to life.

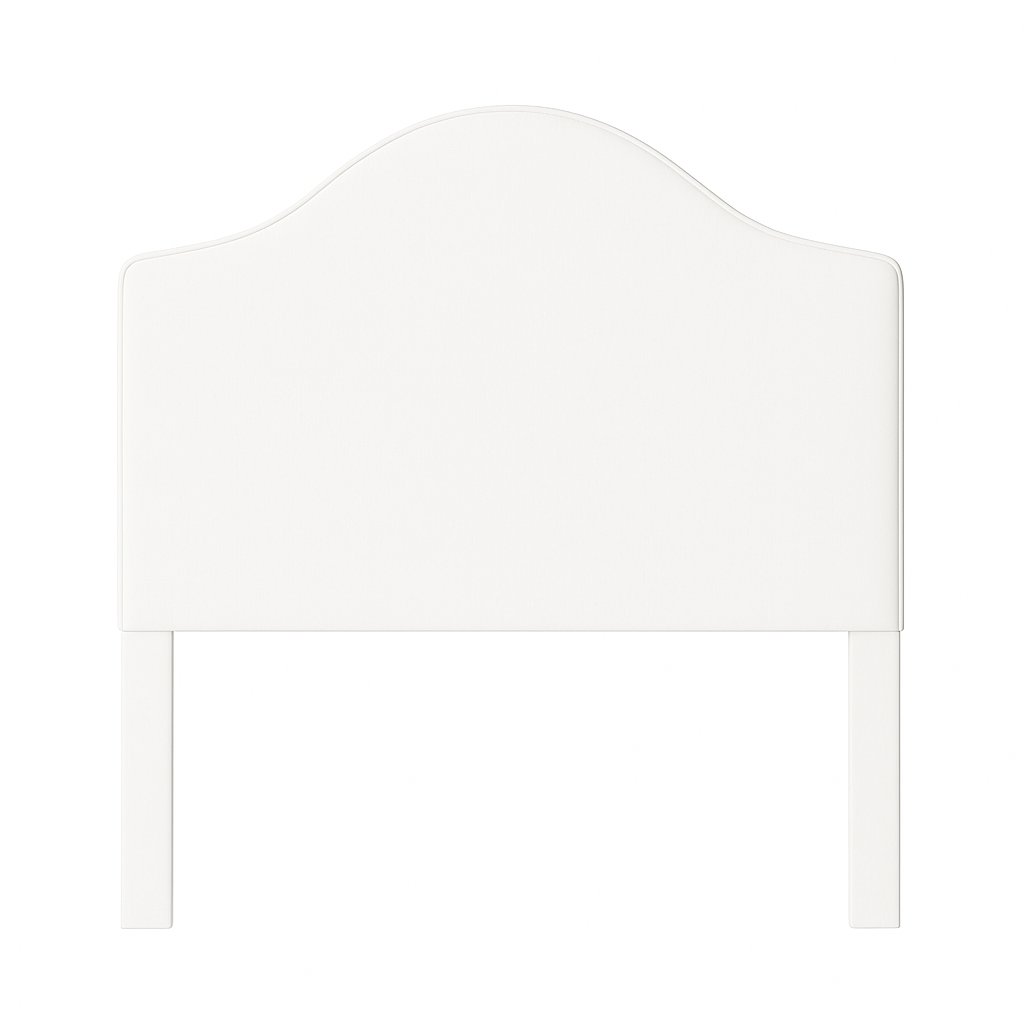

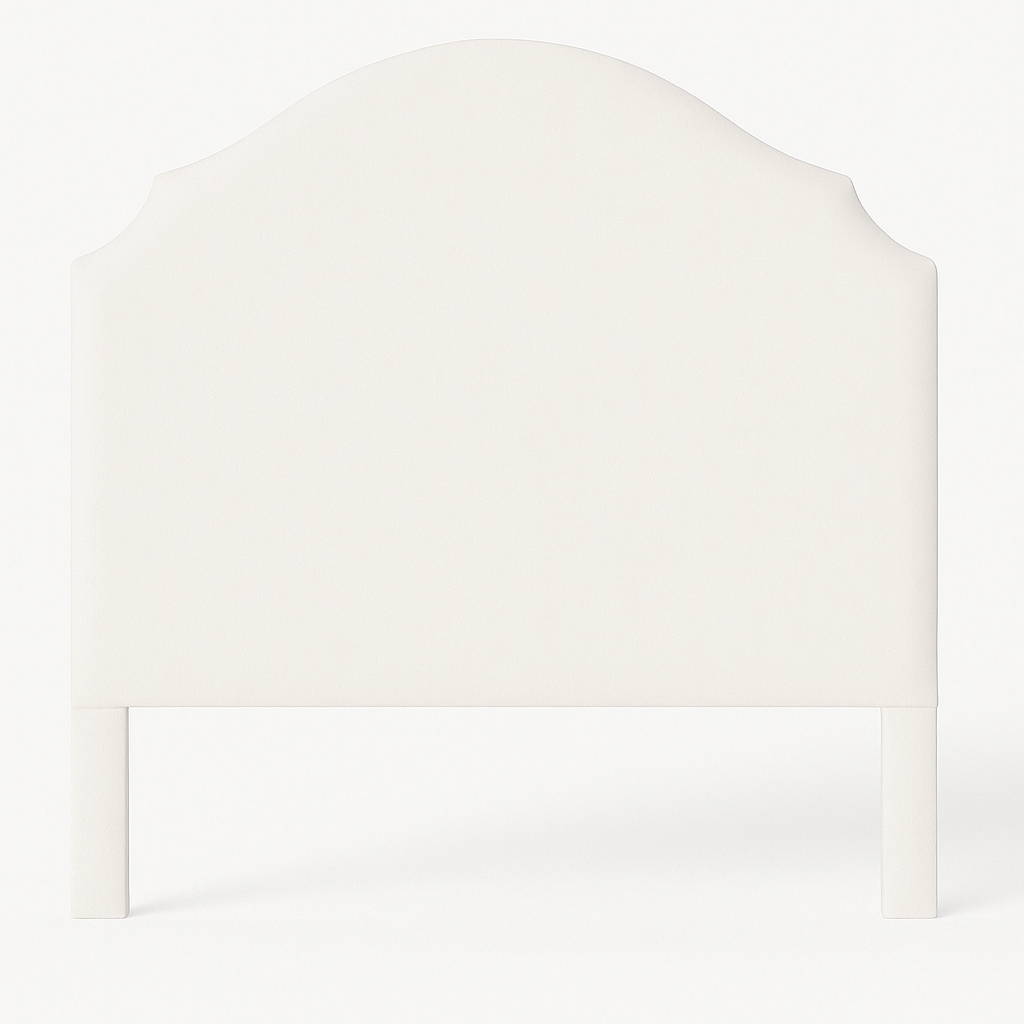

1. It Starts With the Frame

Our name says it all: Fabric & Frame. And the frame is where we begin.

Each headboard starts with a kiln-dried timber base, custom-built to your size and style. We work with skilled local carpenters who craft each frame by hand — strong, smooth, and made to last.

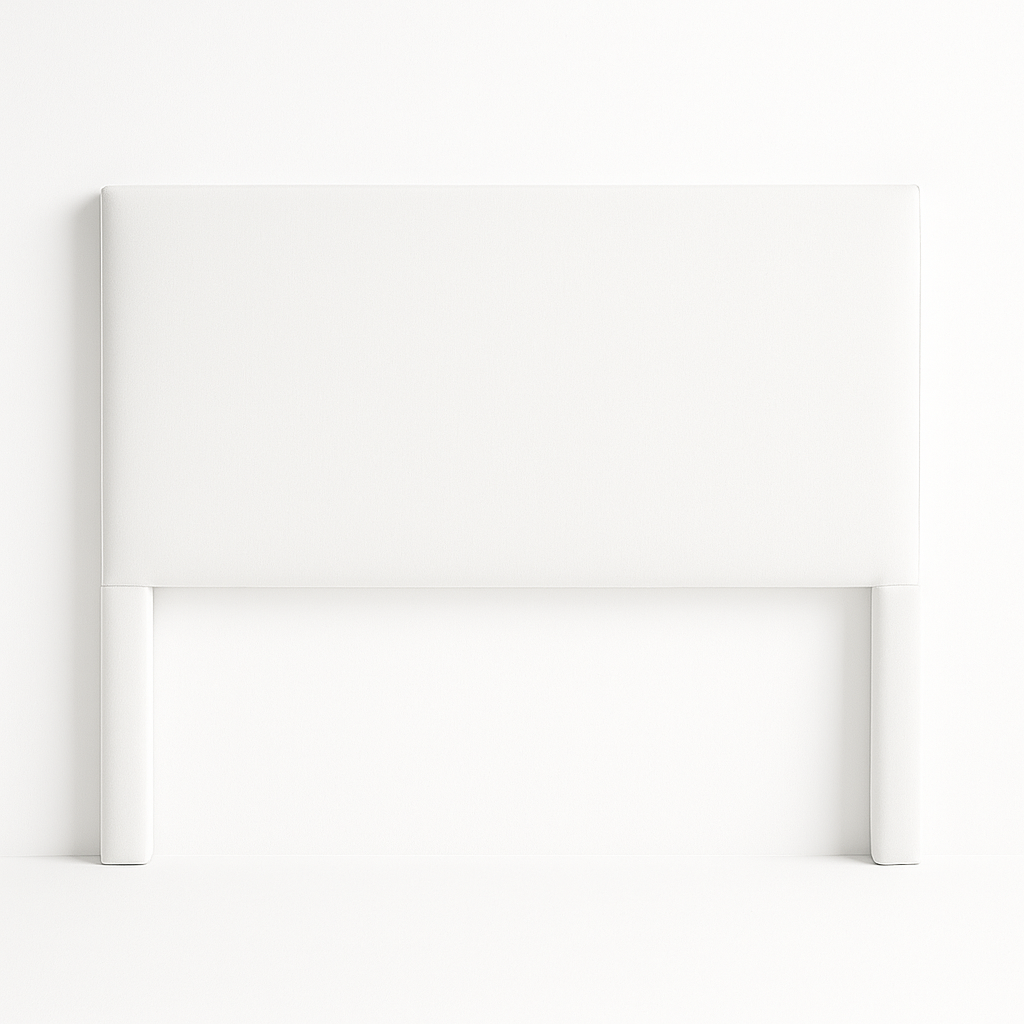

2. Padding for Comfort

Next comes the padding. We layer high-density foam and batting to ensure just the right amount of softness — enough to lean against comfortably, but firm enough to keep its shape for years.

It’s a subtle but crucial detail that sets a quality headboard apart.

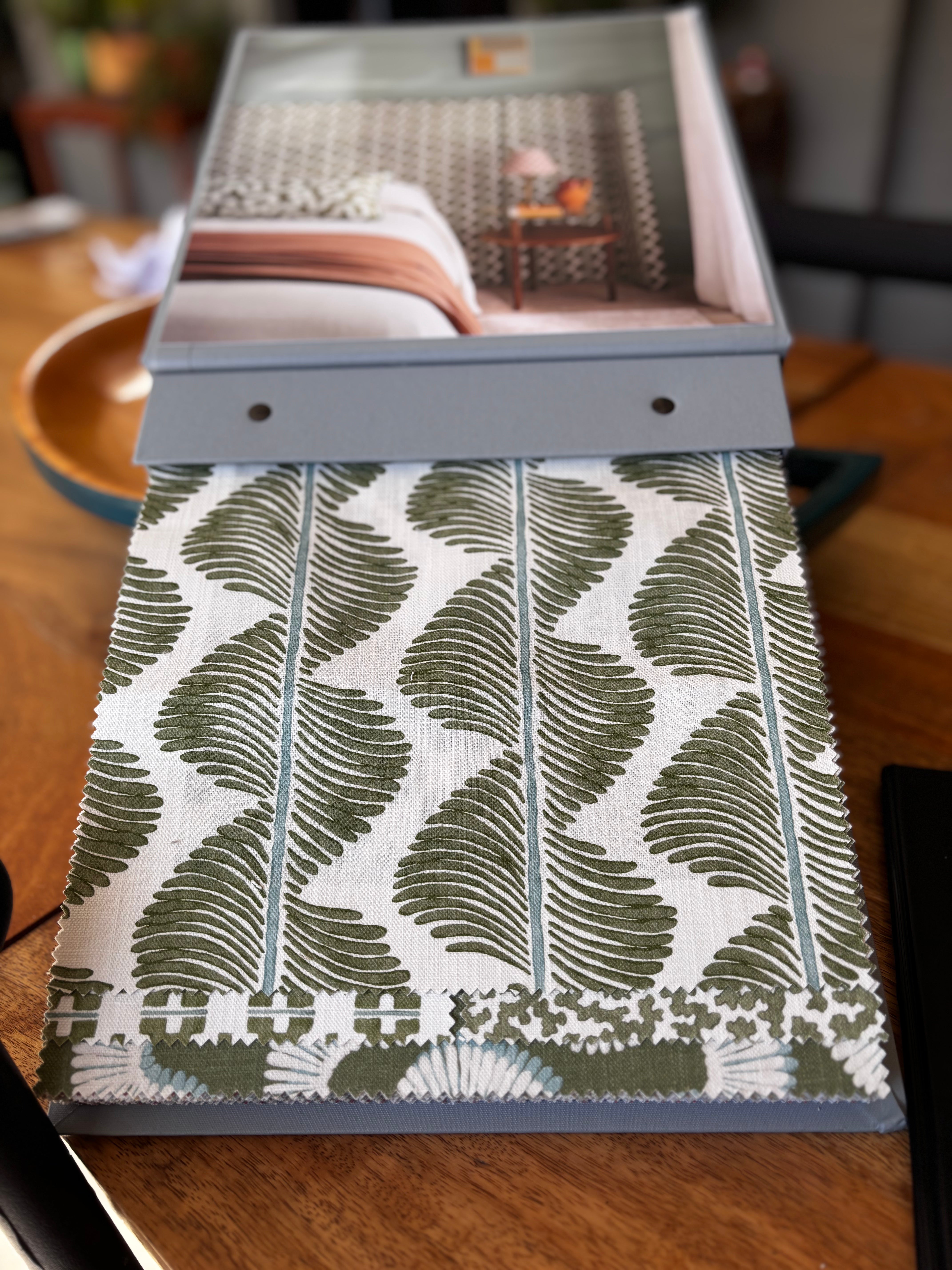

3. Fabric, Cut and Sewn by Hand

Now the magic begins. Your chosen fabric — be it a soft green gingham, a floral linen, or a bold multi-stripe — is carefully measured, cut, and upholstered by hand.

We work with experienced upholsterers who know fabric inside out — how it stretches, how it folds, and how to align patterns perfectly so the end result looks polished and refined.

No piping (unless you request it). No staples showing. Just clean, tailored lines and precise corners.

4. Final Touches and Delivery

Once upholstered, we inspect every headboard by hand. If it’s not perfect, we redo it. Then we wrap it securely and deliver it straight to your home.

No flatpacks. No assembly required. Just unwrap and enjoy.